Weaving is formed by weaving warp and weft yarns on the loom and is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. In order to reduce the friction generated during weaving and prevent the warp yarn from breaking, we need to sizing the warp yarn first to increase the conformability and flatness of the warp yarn. To improve the weavability of the yarn, the effectiveness of weaving and the quality of the fabric.

Sun Chemical cooperates with C&D International Chemical Industry to provide professional slurry and additive of textile sizing field, not only solve customer`s problem by customized solution but tracking all the processes continuously.

Mission 1: To provide new product development sizing program for a customer

Mission 2: customize size produce based on customer requirement

Mission 3: To provide sizing yarn testing and analysis service

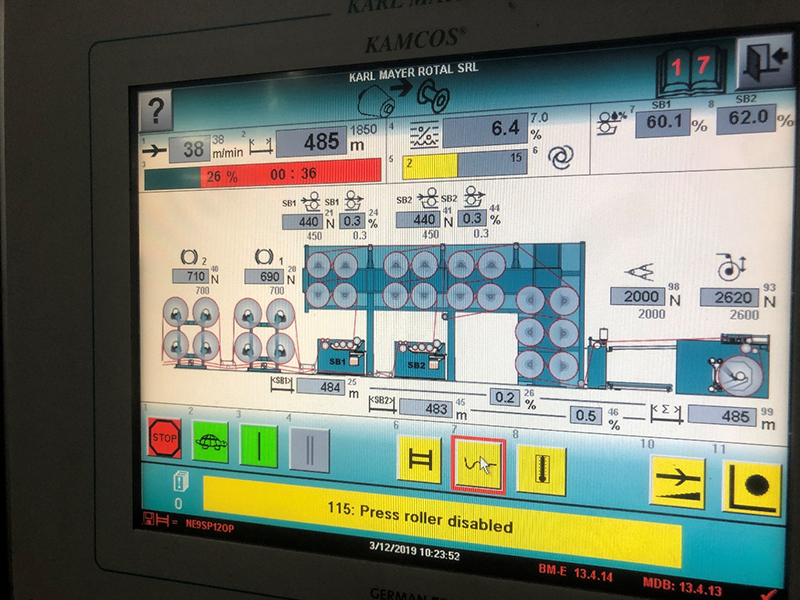

Mission 4: Tracking and continuous improvement

-

Bring the yarn samples back and analysis the sizing process of customers

-

Test the yarn sample in Lab

-

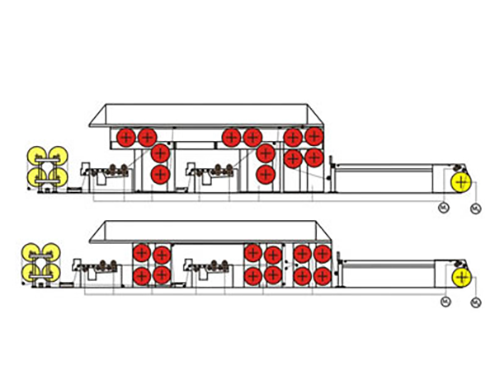

According to the test results, offer two or more solutions, which are tested on our small sizing machines in Lab.

-

Tests on sizing yarns for resistance, elongation, reinforcement, hairiness, etc.

-

Slicing test of sizing yarn using high power electron microscope

-

Technical engineers and customers will decide the best solution which based on complete test data, and determine the final sizing formula according to the customer's sizing machine and weaving machine.

256 bit ssl encryption

256 bit ssl encryption